Pre-Engineered Building (PEB)

To build high quality and cost-effective solution of Pre-Engineered Steel Buildings.

Pre-Engineered Buildings (PEB)

Pre-engineered buildings offer exceptional design flexibility and significantly reduce construction timelines, from concept to completion. These structures are delivered as a fully finished solution, encompassing the steel framework, building accessories, and roof cladding. There is no need for on-site fabrication or welding, as these structures are easily assembled by bolting the components together according to specifications. This ensures consistent quality, durability, and precision in every project. Additionally, their modular nature allows for straightforward expansion, relocation, and cost-effective maintenance.

PEB Advantages

Pre-engineered buildings (PEBs) offer several advantages, including faster construction, lower costs, and high durability. Their off-site fabrication and streamlined design contribute to these benefits.

-

Swift Construction

-

High Durability

-

Cost-Effective

-

Quality Assurance

-

Low Maintenance

-

Energy-Efficient

-

Sustainability

-

Design Flexibility

-

Maximum Space

-

Aesthetic Appeal

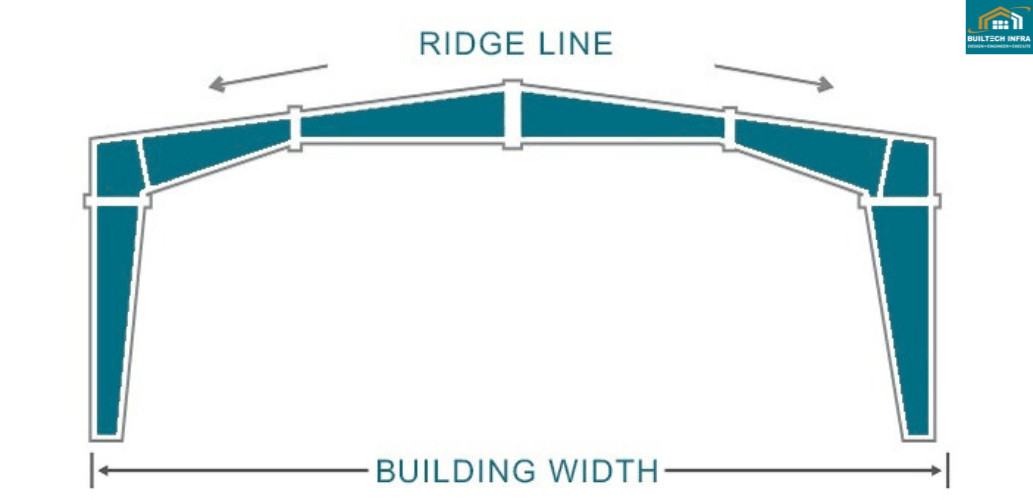

Primary Framing System

Primary members form the core structural framework of a Pre-Engineered Building (PEB). These include columns, rafters, crane beams, mezzanine beams, and other essential support components. Each section is precisely fabricated from high-strength steel plates using advanced, state-of-the-art manufacturing technology to ensure superior quality and performance.

Primary Frame Types

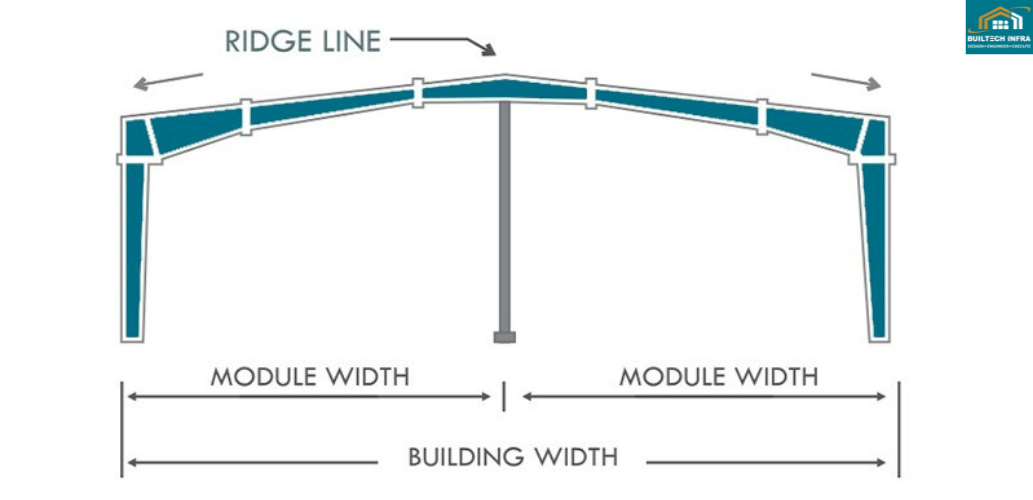

Multi Span 1

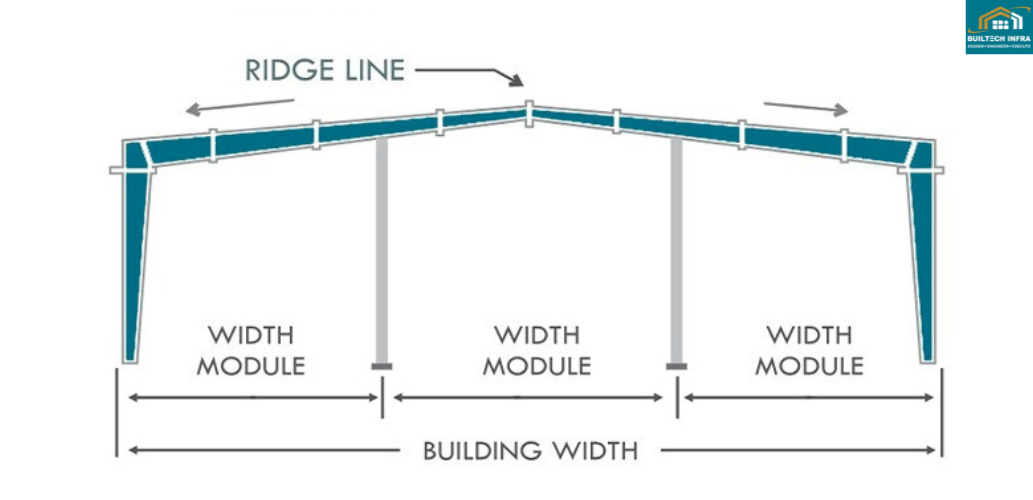

Multi Span 2

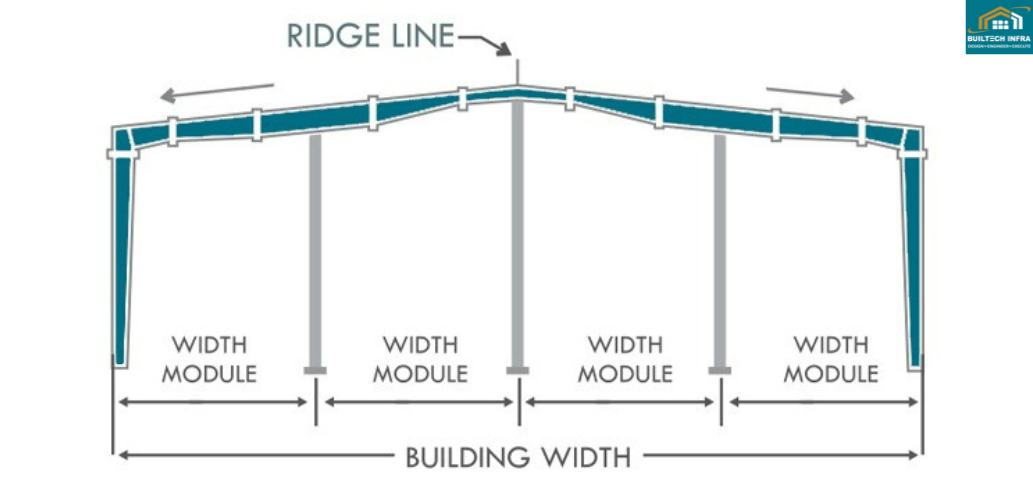

Multi Span 3

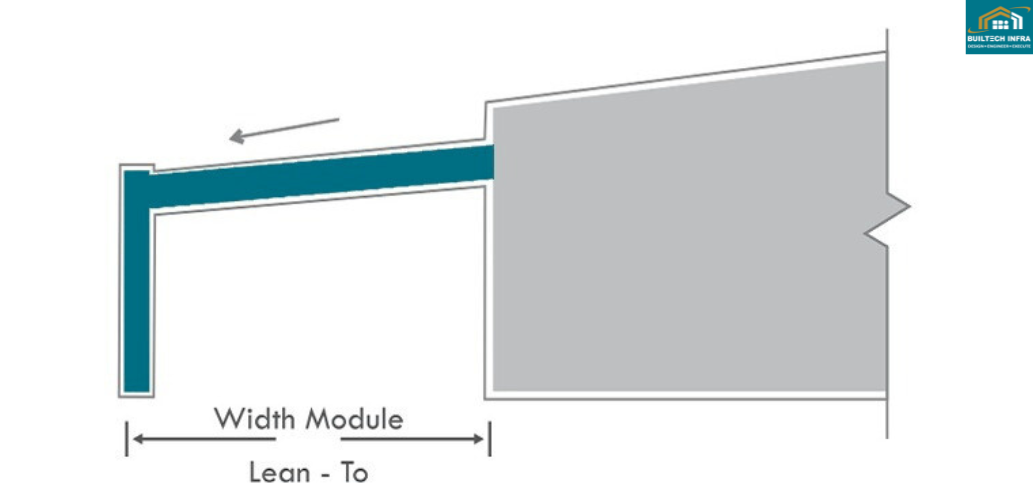

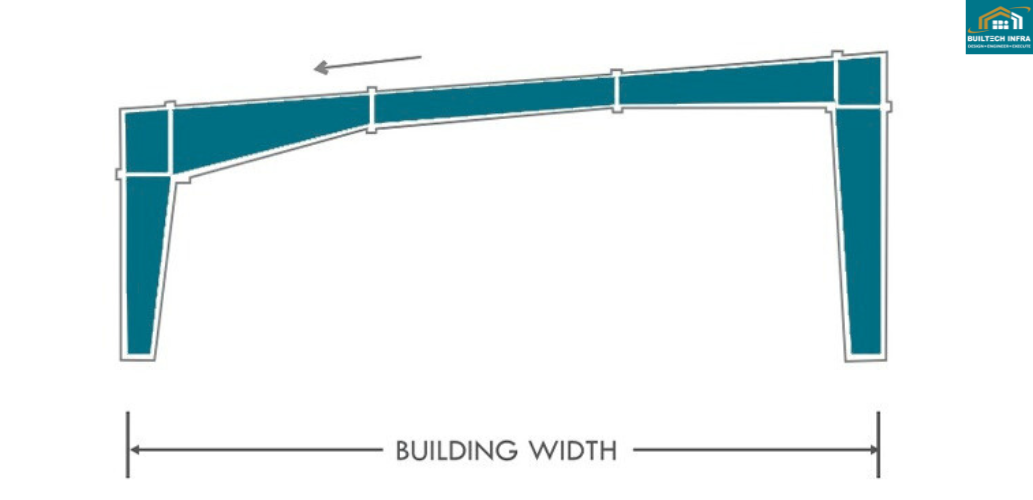

Rigid Frame Lean To

Mono Slope

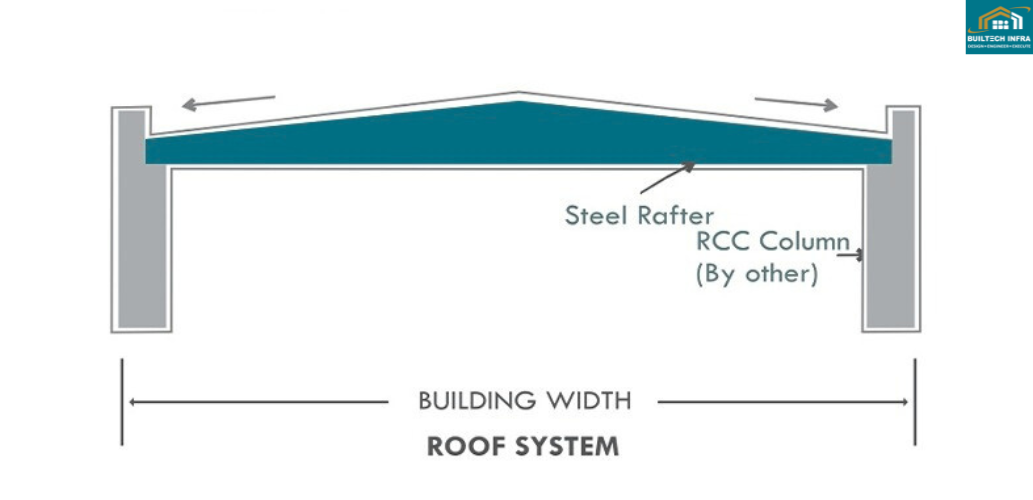

Rafter System

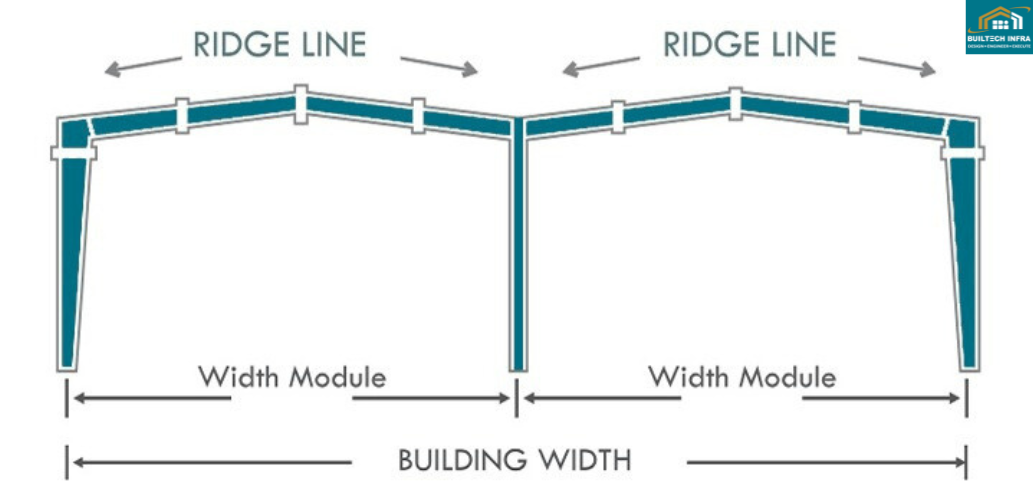

Multi Gable (MG) 1 / 2

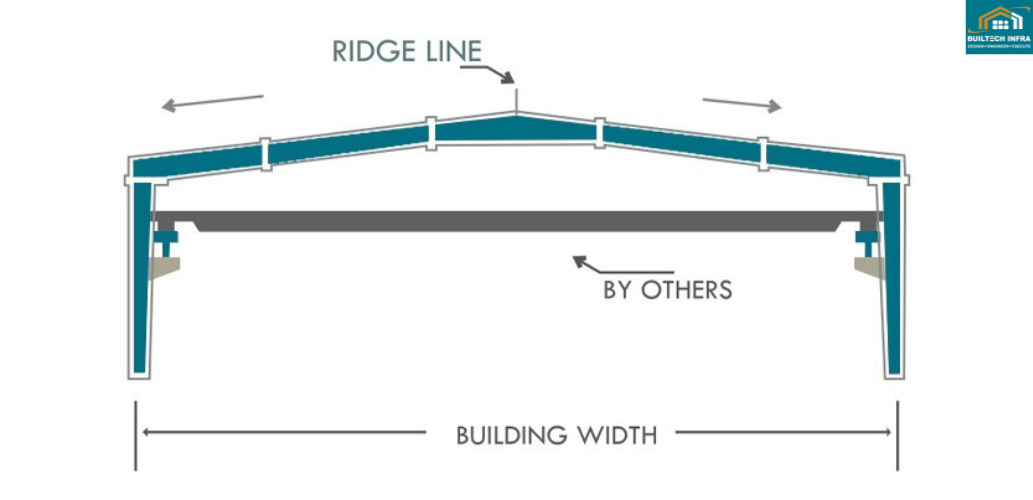

Tapered Column Clear Span

Clear Span with Crane

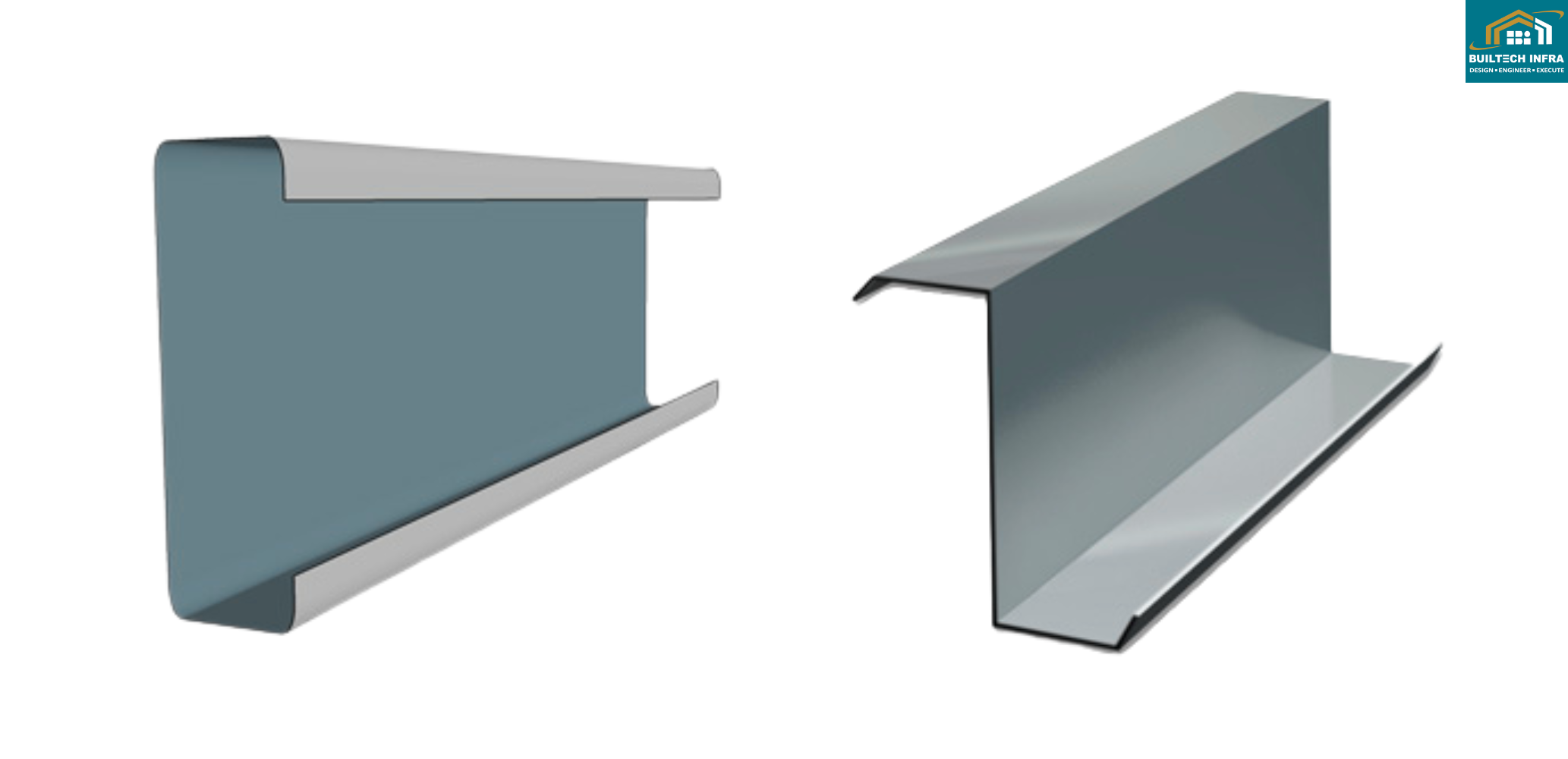

Secondary Frame Members

C and Z Sections

Purlins, Girts, Eave Struts, and Brace Rods serve as secondary structural members, providing essential support to the roof and wall panels. Purlins are positioned along the roof, Girts are installed on the walls, and Eave Struts are placed at the junction where the roof and wall panels meet, ensuring structural stability and uniform load distribution.

Roof & Wall Sheeting

Roof and Wall Sheeting

Roof and wall panels are made from profiled steel sheets, manufactured using high-quality steel coils that are hot-dip galvanized. Each sheet features a minimum AZ150 zinc-aluminum coating, ensuring exceptional corrosion resistance, durability, and long-term performance.

Sandwich Panel

Sandwich panels offer significant savings on energy and operational costs by effectively maintaining the building’s internal climate, reducing the need for extensive heating or cooling systems. Available in thicknesses ranging from 30 mm to 120 mm, these panels are highly durable and engineered to withstand even the most demanding weather conditions.

Standing Seam Roof System

The double lock standing seam system eliminates the risk of leakage at fastener points along sides and ends, providing superior protection under all weather conditions. Designed with full-length panels running continuously from end to end, it ensures consistent weather tightness and delivers virtually maintenance-free performance for years to come.

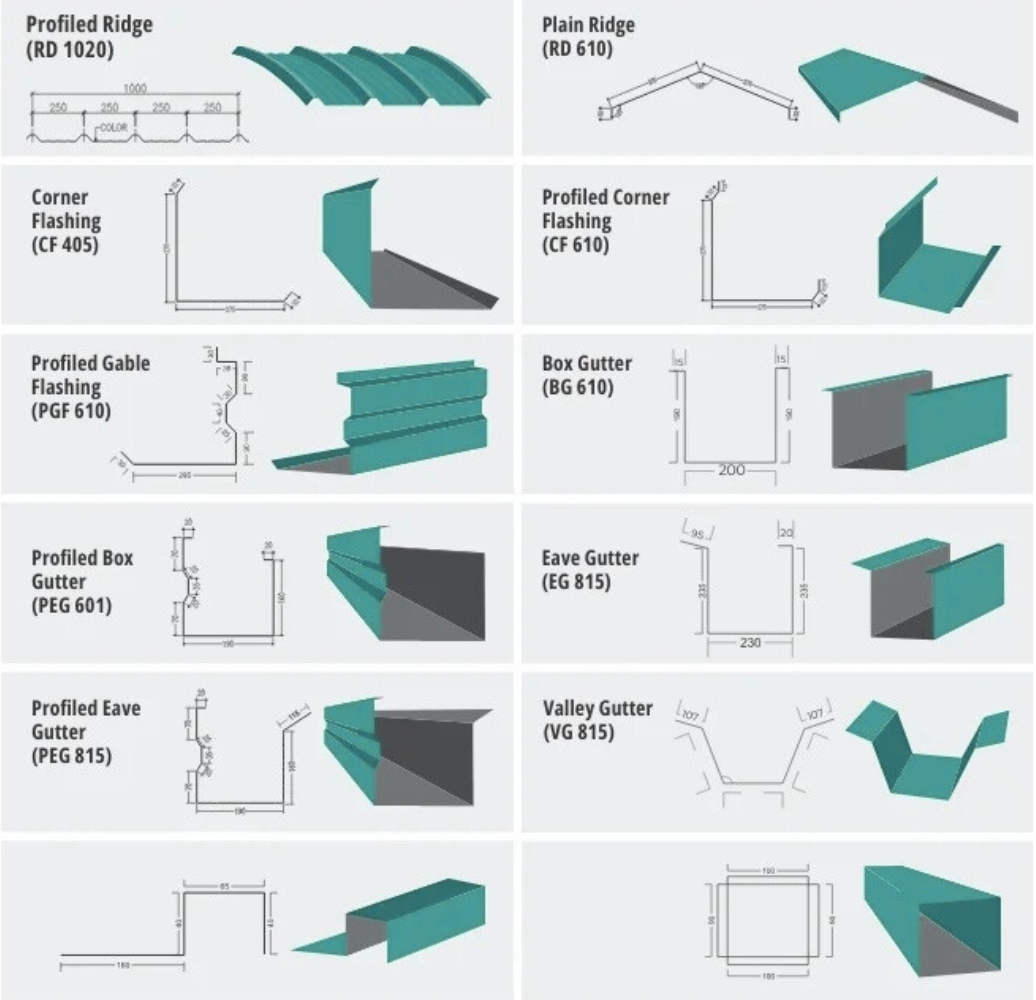

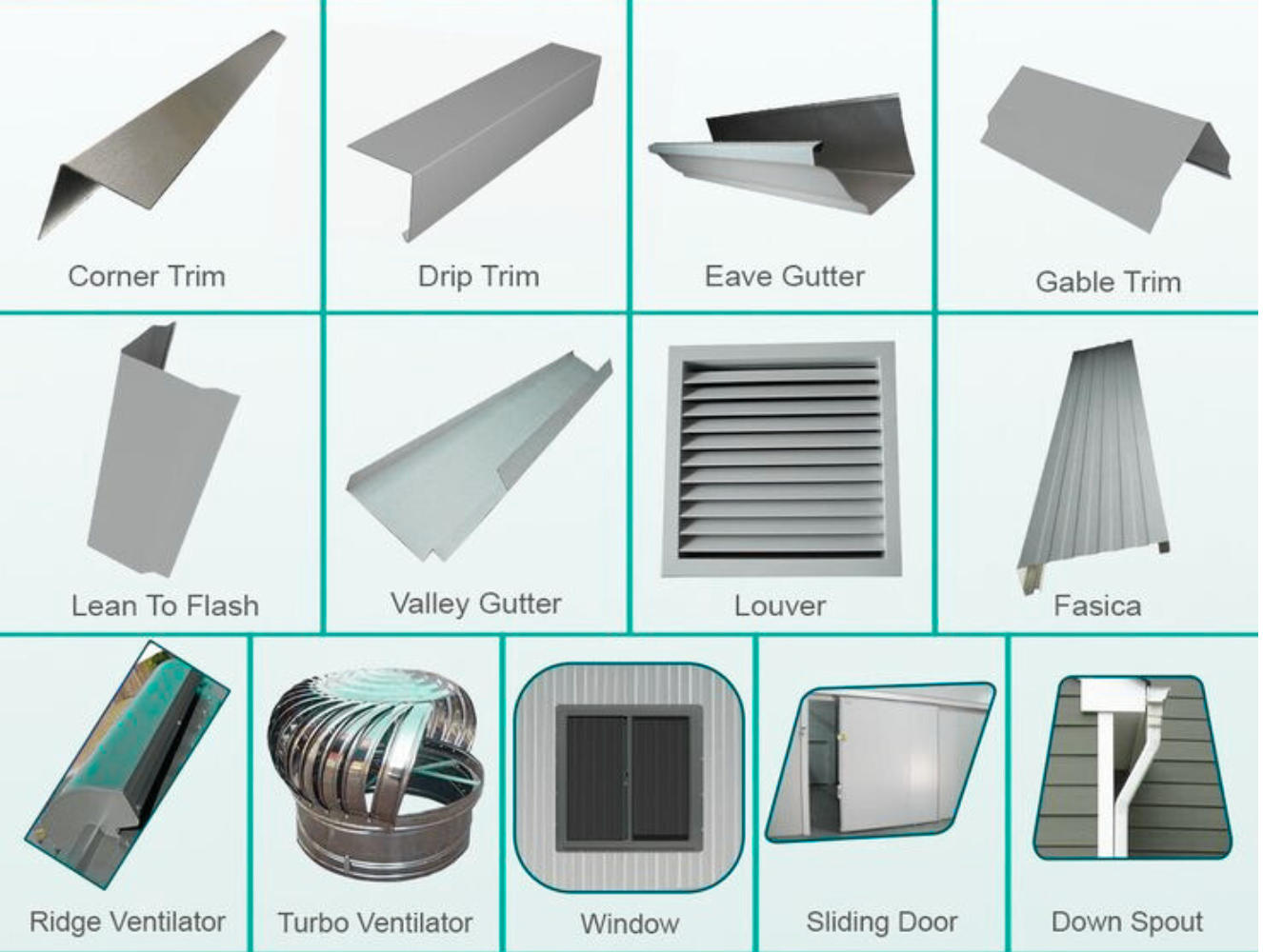

Trims & Flashings

PEB Accessories

Are You Ready To Implement

Your Next Project?

Get in touch